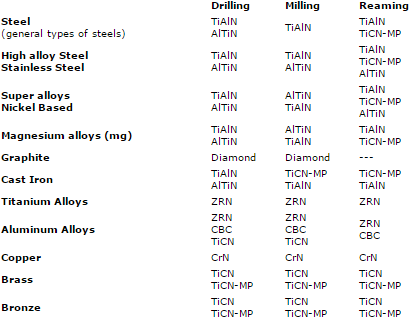

TJ Grinding, Inc. offers tool coating used in all types of applications for our product line of milling, drilling and reaming. Our coating process improves, protects, and strengthens the tools surface properties. The coating will not affect original performance as it is applied at 0.00020 in.

Once completed, our carbide tool coatings are then inspected using Optical Comparators, RAM Optics, and a Laser Micrometer. Additional measures are taken to meet certification requirements for companies requiring it, such as the Medical Industry. Material spec sheets and TJ Grinding, Inc. inspection Sheets are also provided for submission if required.

Since 1982 TJ Grinding, Inc. has been manufacturing and sharpening carbide and HSS Cutting tools. Our manufacturing facility contains the most up to date CNC grinding and inspection equipment. We are committed to manufacturing and sharpening the highest quality cutting tools possible while offering competitive pricing and unequaled customer service.

Our primary goal of Customer Satisfaction is achieved by producing ultra-precise (to the .0001 of an inch), high quality cutting tools in the most cost effective manner possible. But price and quality both mean very little if your tools are not delivered when you need them. This is why T.J. Grinding, Inc. offers lead times unmatched by many in the industry on both custom and standard cutting tools.